Butech Bliss - News & Articles

Butech Bliss Announces Acquisition Of LM Equipment & Design, And Lehmann Mills

LM Equipment is an OEM dedicated to designing and building coil processing machinery and systems for the metals industry. This acquisition gives owners of PAXSON equipment access to Butech Bliss’ services to better maintain this equipment...

Lehmann Mills manufactures high quality dispersion mills and has built more than 5,000 in its 100 plus year history. Lehmann also offers quality service, reconditioning and spare parts service, for not only their mills but for any brand dispersion mill...

click for article >>

Feralloy/Acero Prime Orders Butech Bliss Stretch Leveling Cut-To-Length Line and Slitting Line for Their New Sinton, Texas Facility

The new stretch leveling cut-to-length line is rated up to 1 inch thick by 84 inches wide and can produce sheets 40 feet long inside the stacker. The line features a patented Synergy® hydraulic roller leveler capable of handling the entire product range in a single leveler, and is complete with a quick change roll cartridge system to minimize maintenance downtime. The Butech Bliss stretch leveler features a 50 foot stretch bed and 2,800 tons of stretching force...

click for article >>

Butech Bliss Commissions State-Of -The Art Stretch Leveling Line At Feralloy’s Ghent, Kentucky Service Center

The new stretch leveling line features material handling, entry and exit equipment, along with a Synergy® hydraulic roller leveler, equipped with hydraulic powered independent entry and exit roll settings, closed loop system to compensate for machine deflection, enhanced operator friendly controls and a quick change roll cartridge system. The patented Butech Bliss stretch leveler features a 50 foot stretch bed and 1,900 tons of stretching force and can process up to 1 inch thick by 76 inches wide material...

click for article >>

Butech Bliss Acquires 50,000 Square Foot Manufacturing Facility To Expand Operations

Jock Buta, Executive Vice President of Butech Bliss, was enthusiastic about what this means for his company. “This is going to be a great building for us and finally resolves problems with much needed manufacturing space. We have big plans for the operations moving into this space...

click for article >>

Butech Bliss Completes The Installation of Custom Steel Processing's New Stretch Leveling Cut-To-Length Line

Butech Bliss has just completed the design, manufacture, and installation of a high production Stretch Leveling Cut-To-Length Line for Custom Steel Processing’s new coil processing center in Granite City, Illinois. The line will process a wide range of products including hot rolled carbon steel, HRPO, cold rolled steel and galvanized steel up to 1” thick and 74” wide. This state-of-the-art line includes Butech Bliss’ patented Synergy® Leveling...

click for article >>

Fulton County Processing Selects Butech Bliss To Build Their New Slitting Line

Fulton County Processing (FCP), a northwest Ohio-based, state-of-the-art steel coil processing company, has announced it will be installing a new high production slitting line set to be operational in the second quarter of 2019. The multi-million project will require a 70,000+ square foot expansion to the plant, which will house the new line and provide additional storage space. Once the new slitting line is completed, the project is expected to create 25 new jobs over the next 3 years...

click for article >>

Custom Steel Processing Selects Butech Bliss To Build Their New Stretch Leveling Cut-To-Length Line

Butech Bliss has been selected to design, manufacture, and install a high production Stretch Leveling Cut-To-Length Line for Custom Steel Processing’s new coil processing center in Granite City, Illinois. The line will process a wide range of products including hot rolled carbon steel, HRPO, cold rolled steel and galvanized steel up to 1” thick and 74” wide. This state-of-the-art line includes Butech Bliss’ patented Synergy Leveling System® with quick change roll cartridge system and high production stretch leveler. The line also features a brush scale collection system and a direct drive shear with our exclusive cam shaft design and quick change knife cartridge system...

click for article >>

Samuel Nelson Technology, a Division of Samuel, Son & Co., Limited and Butech Bliss Form Strategic Bidding Agreement

Butech Bliss and Samuel Nelson Technology are pleased to announce a new strategic bidding agreement. Both parties will jointly market and sell push-pull, semi-continuous, and continuous pickling lines in the United States, Canada, and Mexico. “With Butech Bliss’ innovative processing equipment technology and Nelson Technology’s vast experience in designing and operating pickling lines, the combined expertise makes our partnership an ideal combination as a supplier of steel pickling equipment,” states Al Waigand Vice President of Sales and Marketing at Butech Bliss...

click for article >>

High-Volume Steel Processor Realizes a Win-Win Situation by Installing Heavy-Gauge Stretcher Leveler

Remember the 1970’s toy, Stretch Armstrong? Kids loved this action figure because its limbs could stretch and then return to original form. With heavy-gauge metal, however, one stretches it so it doesn’t return to its original form—which follows the contours of a mill coil, includes wavy edges, center buckle and crossbow. None of these conditions are wanted after the material is cut to length and shipped to laser processors. Feralloy Corp., a Chicago-based toll processor and large-volume distributor with eight plants across the United States and Mexico, has seen the tolerance...

click for article >>

Butech Bliss Showcases New $1.3 Million Dollar Equipment Investment

Butech Bliss held a ribbon cutting ceremony for its new $1.3 million dollar machine this past November that represented the largest investment Butech Bliss has ever made in a completely new machine. The Okuma Multus B550 is a multi-functional turning center, which combines the capabilities of a mill and lathe and can process parts up to 118 inches long and 32 inches in diameter. John Buta, president, said the machine, which is capable of handling 9,000-lbs pieces, will open new markets for Butech Bliss and will operate more efficiently and at less cost than other machines doing the same work...

click for article >>

Haynes International Purchases New Equipment To Upgrade Cap Line

Haynes International has selected Butech Bliss to engineer, manufacture and install upgrades to convert their existing Butech Bliss push pull pickling line that was installed back in 1988 into a continuous anneal and pickling line. The upgrades will include adding an annealing furnace, kolene salt bath section, and a welder on the entry end of the existing push pull pickling line. Butech Bliss will also be providing the required strip processing equipment which includes the entry and exit accumulator towers and four sets of bridle rolls. Once the equipment upgrades are completed Haynes will have the ability to run the anneal and pickling line in a continuous mode or operate the pickling line...

click for article >>

Restoration Of Copper Crucibles Proves To Be A Growing Business

If you’ve been in the Butech Bliss facility recently it’s likely that you’ve noticed copper being fabricated or machined. The copper-based melting equipment repair and replacement business has been steadily growing and gaining new customers. Butech Bliss has been able to utilize talents amongst our employees to service an industry that has sorely needed a reliable supplier over the last several years. The melting or “re-melting” of many specialty or exotic metals often takes place under controlled conditions inside of a water-cooled copper vessel. These vessels are typically a key part of melting systems known as VAR (Vacuum Arc Remelt), ESR (Electro-Slag Remelt), PAM (Plasma Arc Melting) and EBM (Electron Beam Melting)...

click for article >>

Recently Commissioned Champagne Metals 111" Aluminum Cut-To-Length Line

Champagne Metals, a leading aluminum service center based in Glenpool, Oklahoma, recently commissioned their new state-of-the-art 111 inch wide Cut-To-Length Line at its newly constructed Middlebury, Indiana facility. This line is one of the widest aluminum Cut-To-Length lines in North America and will satisfy the ever growing demand of aluminum material by the marine, commercial transportation, consumer electronics and appliances industries. The Cut-To-Length Line will feature entry equipment, over and under coil payoff capabilities, a hydraulic crop shear with auto-gap adjustment, side trimmer (up to 8” per side), scrap chopper, hydraulic roller cassette leveler and direct drive flying shear...

click for press release >>

Feralloy Purchases Stretch Leveler & Synergy® Hydraulic Roller Leveler

Feralloy has selected Butech Bliss to upgrade their existing cut-to-length line in Huger, South Carolina. The upgrades will include a Synergy® hydraulic roller leveler, equipped with hydraulic powered independent entry and exit roll settings, closed loop system to compensate for machine deflection and enhanced operator friendly controls. The patent pending Butech Bliss stretch leveler features a 45 foot stretch bed and 1,850 tons of stretching force. The stretch leveler also is equipped with the Hawkeye™ Flatness Detection System...

click for press release >>

One Inch Plate No Problem For Butech Bliss Stretch Leveler

The stretch leveling cut-to-length line, dubbed, “The Memory Eraser” recently underwent some exciting upgrades. As a result, the four year old Butech Bliss cut-to-length, originally rated to process .750” x 74” x 70,000 lb. hot-rolled, cold-rolled and coated carbon steels, is now processing 1” in. thick material flawlessly...

click for press release >>

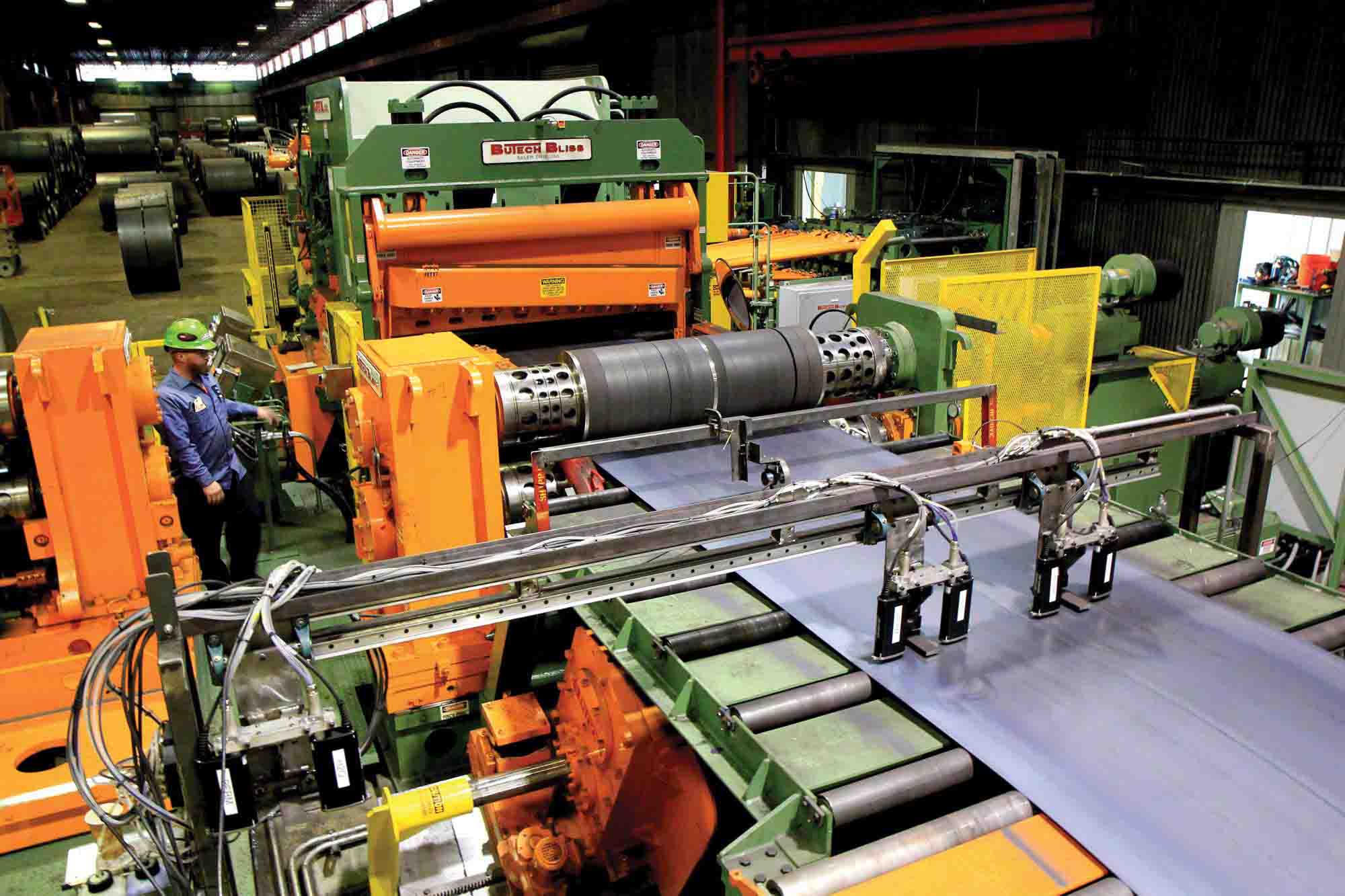

Liberty Steel Selects Butech Bliss To Build Multi-Blanking (Slitting) Line

They have selected us to engineer, design, manufacture and install a state-of-the-art multi-blanking line. The multi-blanking line will feature entry equipment, hydraulic crop shear, hydraulic roller leveler, slitter with interchangeable heads, looping pit and direct drive shear. Installation will take place...

click for press release >>

Butech Bliss Selected To Build Steel Dynamics New Push Pull Pickling Line

Steel Dynamics, Inc.® has awarded Nelson Steel’s Technology Group and Butech Bliss contracts to provide equipment to upgrade the existing hot band finishing line at their Butler, Indiana facility. The upgrade will enable the line to convert hot bands to HRPO coils...

click for press release >>

Butech Bliss Selected To Build FCP’s New HCL Push Pull Pickling Line

Fulton County Processing, a state-of-the-art steel coil processing company, has announced the installation of a new hydrochloric push/pull pickling line set to be operational in early 2015. The $20 million project will require...

click for press release >>